A few months ago, I bought a LulzBot Mini to print parts for a robotics project. Despite its rather goofy name, the machine itself is great, especially for the price. However, it does suffer from the same inaccuracies that are fairly common among typical 3D printers. Since many of my parts had to be precisely fitted, the noticeable differences between desired and actual dimensions were problematic.

The good news is that these imprecision are fairly consistent, and after some tinkering I figured out a few rules of thumb for sizing dimensions. For the record, I tested these using Gizmo Dorks 2.85mm HIPS filament on high print quality in Cura.

Below are some of the different 3D objects I tried to print and the resulting inaccuracies. These aren’t very precise measurements, but they should be good to about a quarter millimeter.

Cylinder Extrusion

For printing cylinders, there were no noticeable differences between commanded and actual diameters as long as the cylinder was reasonably thick.

Cylinder Hole

A good rule of thumb for printing cylindrical holes in solids is make the diameter in your CAD software about 0.6mm larger than what you actually want (e.g. specify 6.6mm to end up with a 6mm hole). I’ve tested this for holes between 5mm and 20mm in diameter.

Another thing to keep in mind is that the diameter is narrower at the printing plate than at the top of the hole. For example, I set my hole diameter to 6.6 millimeters in order to snugly fit a 6mm brass pipe inside; it was a perfect fit at the bottom, but had a small amount of slack at the top. This is most likely because the plastic spreads out a bit more when in contact with the printing plate, resulting in a smaller hole.

Rectangular Prism Extrusion

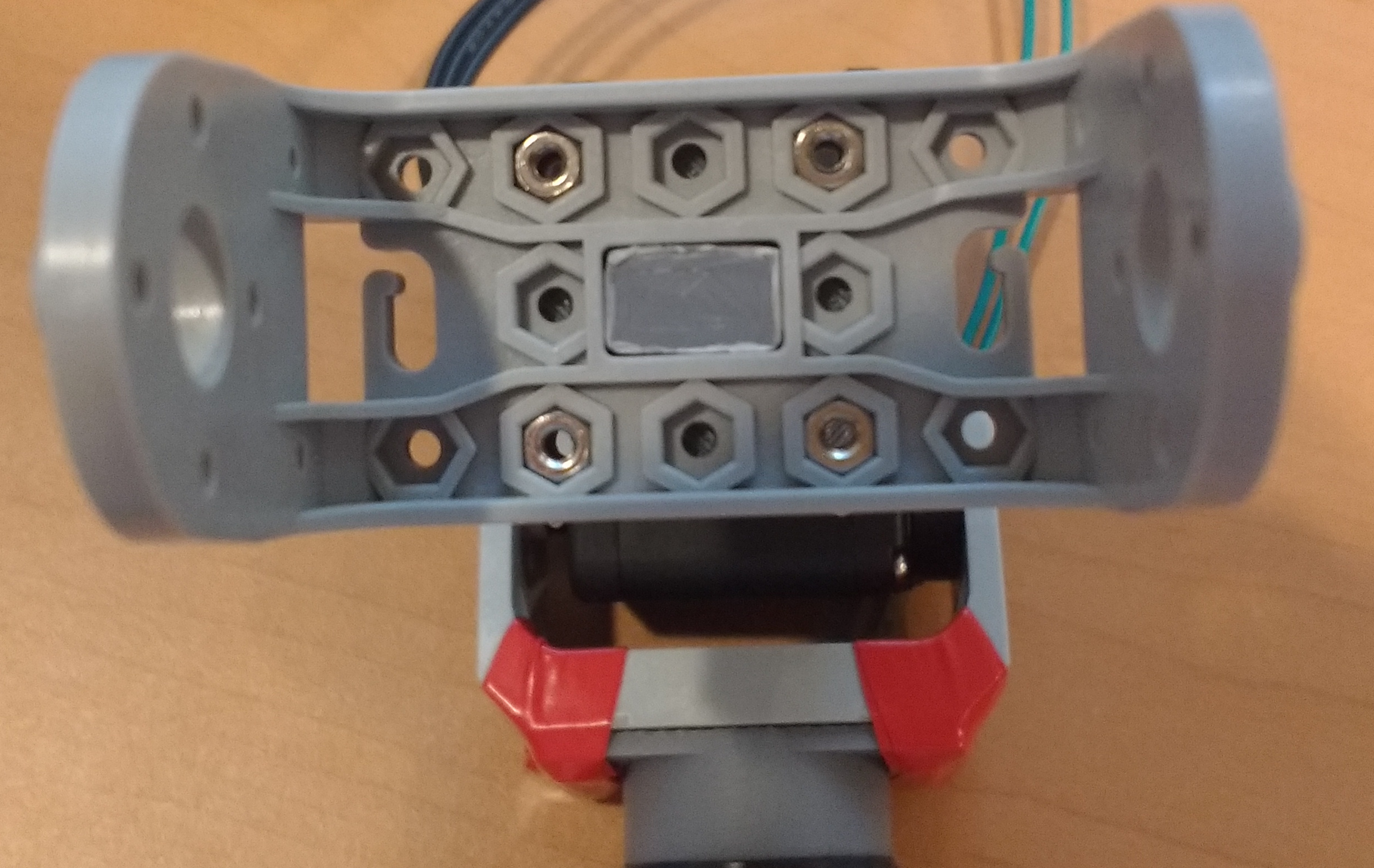

When printing a rectangular prism, the actual dimensions are slightly larger than the commanded ones around the centers of the edges, while the corners are rounded off. When I tested this, I wanted to fit the rectangular hole that’s commonly found in the center of most Bioloid frames. My first attempt was printing the exact dimensions of the hole (10mm x 6mm). This resulted in a slight press fit, which is exactly what I wanted; if you don’t want a press fit, you may have to scale down the dimensions.

Leave a Reply